Strict Quality Control System

We have strict standard of each step of bambu products processing. From raw material to the final products, each board has to be processed more than 20 procedures. And all our workers have more than 5 years experience of manufacturing bamboo plywood, worktops, strand woven boards etc. skills. Therefore they will seriously control by technology data. So we have confidence of our bamboo products with stable and high quality.

Bamboo Raw Material Control

Considering our factory located in the famous Mao bamboo home town, so we have the great advantage to choose the best materials. we strictly ask that all of our bamboo materials is 4-6 years. After many years tried, the 4-6 years mao bambu is the best choice for bamboo plywood, countertop, decoration boards even construction structure material. Because this period bamboo keep the strength and flexibility balance.

Strips & Board Control

Our workers will select pcs by pcs. They pick out the decay, cracked, knots, remained skin strips. For vertical pressed board, we will double select the better board as plywood surface. At the same times, they will match the strips and boards color according to the order demands. Sort out the light or dark color strips. So the finished board will be uniform and beautiful.

Moisture Control

As we known, the moisture content is the key to keep the board stable. So according to different countries climate, we strictly control the kiln dry temperature, the time. After kiln dry, we need to double check in the next steps. If necessary, we will put the strips or boards into the kiln to balance the moisture. Before loaded, our QC will check again to ensure the moisture.

Hot Pressed Control

Hot press is one of important procedure in the manufactory. To avoid the holes and gaps between strips, we have to carefully control the press time, temperature, pressure and time. Also in order to meet E1 and NAUF standard, all the glue we use is eco-friendly and non-toxic. So we can also achieve the FSC certification

Size & Surface Check

After sanding, we will check the thickness, length and width. Besides the basic sizes, we all check the 6-side before packing. especially to decide which surface is A grade. Sometimes our clients will make the decision.

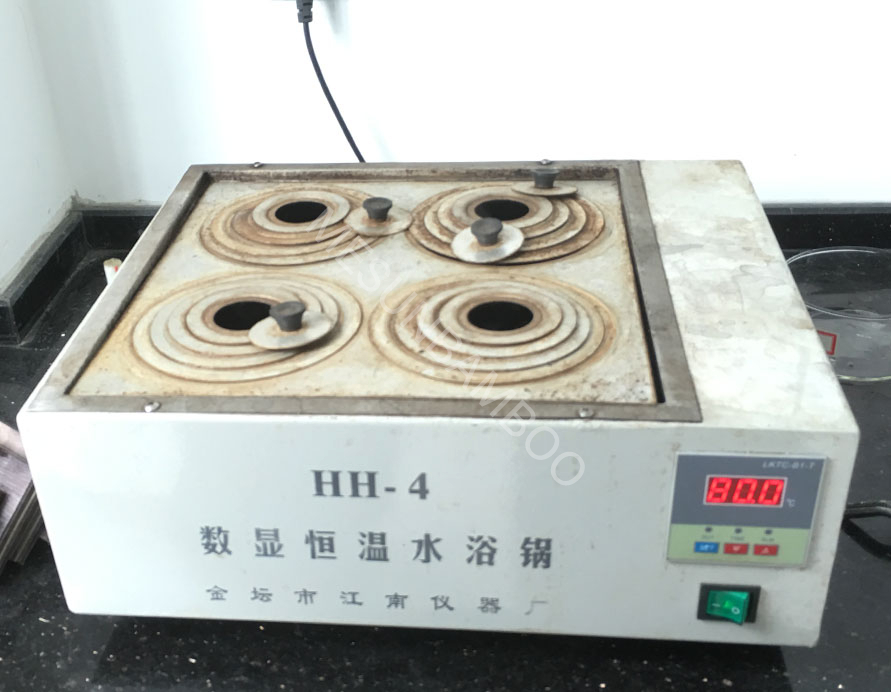

Lab Test

When the board finished, We select the final products randomly for adhesion, moisture control. Normally our QC cut into 6 pcs 150x100mm small board for test. And we will record all the data in the process. If any data doesn’t meet requirement, we will immediately inform our professional department to improve.